3 min read

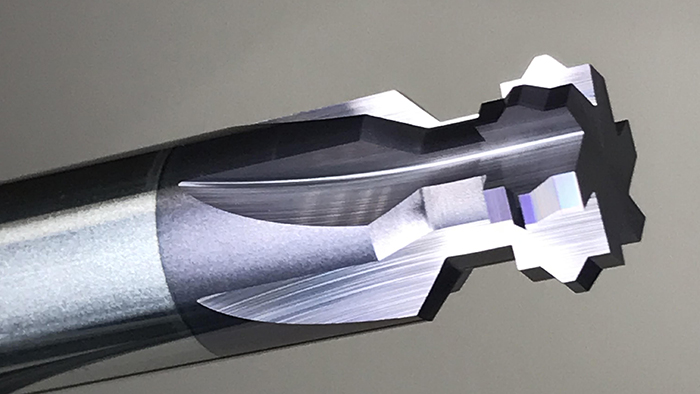

Tool Geometry: Cut and Spiral

Every week we have conversations with customers about how to customizetool designs to help achieve ideal machining...

By: Jennie Gordienko on Nov 3, 2020 1:32:00 PM

Nearly every company we work with has goals tied to continuous improvement. For some that means reducing cycle times on a specific project. For others it means increasing tool life on a long-running job to create significant cost savings throughout the life of the product. In some cases, companies may need to improve tool performance so that fewer operations are needed.

MITGI works with companies every day to help identify the exact needs at hand and offers ways to achieve the goals through cutting tools.

Recently we worked with a medical device manufacturer that was tasked with reducing cycle times during the initial scale-up for production. Learn more about the project and approach >>

Jul 13, 2023by MITGI

Every week we have conversations with customers about how to customizetool designs to help achieve ideal machining...

Jun 6, 2023by MITGI

When applied to cutting tools, a coating can prolong tool life and improve performance. Several different coating...

May 25, 2023by MITGI

Friction has a big impact on the cutting process, and its worst outcome shows as tool wear. If you can manage the...