MITGI Keyseat Cutters

In precision manufacturing, keyseat cutters are used to create slots with square corners, chamfered, with a partial or full radius. In industries like medical device manufacturing, aerospace, automotive, and defense, the keyseat cutters used in production must be designed to achieve part specs, including tight tolerances. MITGI has built its business around the idea that customers need precision tools, tight tolerances, short lead times, and predictable delivery schedules. Whether you need a quick turn, blanket pricing, or want to work with us on a continuous improvement project, MITGI has you covered.

Products and Applications

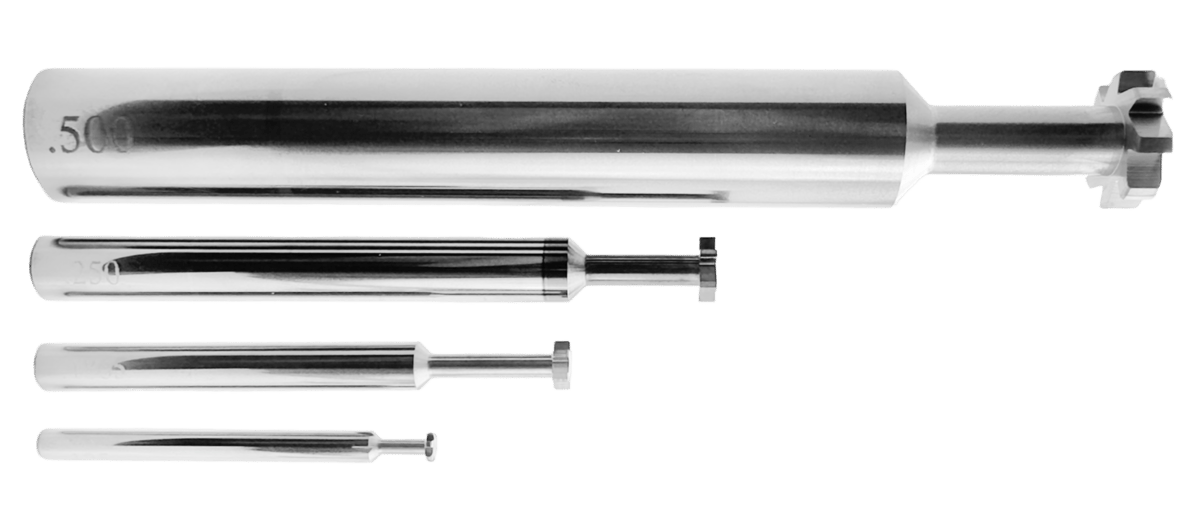

MITGI standard keyseat cutters come in four end finishes: square, corner radius, full radius, and 45° chamfer. Shank diameters range from 0.125 in. to 0.500 in, with overall lengths from 1.50 in. to 4.00 in. As tools become larger, they have larger cutter diameter, longer reach, larger neck diameter, thicker cutter width, and more teeth.

MITGI standard cutting tools include a line of 45° chamfer keyseat cutters (S97-010-45 is shown here). If additional reach is needed, a modified standard may be the answer. Still available in 3-days or less, many MITGI standard tools can be ordered with additional reach for a small charge.

MITGI standard keyseats are available with a square-end finish (the tool shown here is S97-015-SQ-ALTIN). Also called keyways, key cutters, or woodruff cutters, this tool type is used in many precision manufacturing applications to add slots, cut keyseats, or cut the inside of a form.

A standard line of full radius cutters is available in 3-days or less (the tool shown here is S218-003-FR). These tools are often used to create a U-shaped slot or to create a groove.

There are three different options available in the standard MITGI corner radius keyseat cutter line: 0.005R, 0.010R, 0.015R (the tool shown here is S219-056-.015R). Additional radius options are available for custom tools.

FAQs

-

How do you decide whether to use a standard tool or move to a custom?

There are several answers to this seemingly simple question. For example:

- Lead time may be a deciding factor. Our regular lead time for standard tools is 3 days or less, while custom tools are usually available in 2 weeks or less. Regardless of how we quote a tool in normal circumstances, we understand when companies are pressed for time. We don’t charge to expedite, but we will try to accommodate schedules whenever possible. Let us know what you need and we’ll do our best to achieve it.

- Production volume may drive your decision. If you are a high-mix, low-volume facility, a standard tool may be a great option for you. A MITGI standard tool will help achieve tight tolerances and great surface finish and can be used in a variety of materials and projects. If you are a high-volume, low-mix facility, custom tools may be worth considering. When production lines are tasked with increasing tool life, improving cycle times, or increasing throughput, custom tools may help to achieve the goals through application-specific features and geometries.

- Not sure? Just ask. Send us your tool specs, info on the project, and any goals you’re trying to achieve. If a standard tool exists, we’ll let you know. If we see any opportunities for improved performance by moving to a custom, we’ll give you the option to consider.

-

Which end finishes are available on MITGI standard keyseats?

MITGI standard keyseat cutters are available in square, corner radius, full radius, and 45° chamfer end finishes. More options are available for custom keyseats.

-

How can you extend the life of a keyseat?

If your keyseat is working well, but you’d like it to last longer, coating is often a good place to start. It may not be suitable for every material, but the added lubricity and heat control that the coating provides may help to extend tool life. If your tool is already coated, it may be worth considering switching to a different coating. There may be more than one coating that is suitable for a material, and upgrading to a higher-performance coating may help extend life in applications that produce more heat. Learn more about our in-house coating options.

MITGI Custom Tools

In applications where the part is very complex, it’s for a high-volume product, or when it uses a hard-to-machine material, a custom tool may be the preferred option. Custom tools provide manufacturers with the ability to achieve specialized features, geometries designed for specific materials, and to achieve tool life or surface finish goals. Count on MITGI to provide accurate custom tools, achieve tight tolerances, and are usually available in two weeks or less.

Getting started is easy. Contact us to discuss your custom tool request. Or, complete a tool quote sheet and send it our way. We’ll review the information, connect with you regarding any questions we may have, and send a quote to you promptly.

Quote Sheets

Keyseat Cutters, Woodruff Cutters, Keyway Cutters

MITGI Standard Tools

MITGI standard tools are designed for general-purpose use. They are an excellent choice when lead times are very short (3 days or less), or when the tool may be used in a variety of materials and applications.