2 min read

Avoid out-of-tool disruptions and stabilize pricing with blankets

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...

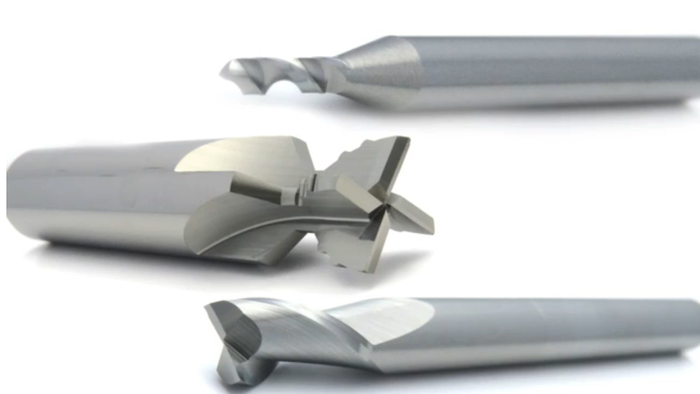

Machining operations require tough, durable carbide cutting tools that perform each job perfectly with uncompromising precision. The question is, can standard tools do the job, or is a customized tool, designed specifically for your application and material, worth the investment? Here are some factors to weigh as you decide.

One of the biggest advantages of standard tools is their short lead time. MITGI carries an inventory of commonly used, standard cutting tools that are typically available and ready to ship. If a standard tool is not in stock, MITGI can put the tool into manufacturing, producing it in three days or less.

With the right partner for custom tools, the process does not take much longer. MITGI maintains a large inventory of carbide blanks and leaves room in the production schedule for tools with short lead times. The normal lead time for custom tools is two weeks, and depending on the tool type and current production schedule, may be as short as a few days.

Some jobs are more challenging than others, and one of the biggest factors is the material being cut. In machining situations where the material is not particularly demanding, a standard, general-purpose tool is a good option to consider. Standard tools are designed to provide the flexibility to use them in multiple materials and applications. When machining difficult materials a custom tool may be preferred and a material-specific geometry can be applied.

Whether using a standard or custom tool, it may be possible to improve the tool’s performance by applying the coating best suited for the material being cut. MITGI in-house and outsourced coating options can help extend the tool life and reduce heat for many commonly utilized materials:

If you are looking for a tool that can be used in multiple materials, applications, or for a short run job, a standard tool may provide sufficient performance. For long running jobs, demanding materials, or when you want to extend tool life, a custom tool is the best option.

The key to getting the most out of a custom tool order is to coordinate and share information with your tool designers. MITGI engineers have experience analyzing wear patterns and can make recommendations that can be tested and then iterated upon until the best solution is found.

MITGI specializes in customizing tools, quick-turn specials, and partnering with companies on long-term strategic improvement. When you need a custom tool, turn to MITGI to:

There are projects where standard tools are perfect. They’re readily available and pricing is low and predictable. However, partnering to create custom tools does not have to create havoc for your operations. Reorders can generally be carried out quickly and the return on investment can be significant if you select a manufacturer that has the expertise to dramatically improve your parts per tool or meet other selected goals.

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...

Mar 27, 2025by MITGI

High-volume, low-mix production environments count on predictability to keep their long-running jobs profitable and on...

Mar 4, 2025by MITGI

When jobs run for many months or years, it may be worth exploring whether there are advantages in moving to a higher...