2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

By: MITGI on Feb 24, 2025 2:20:39 PM

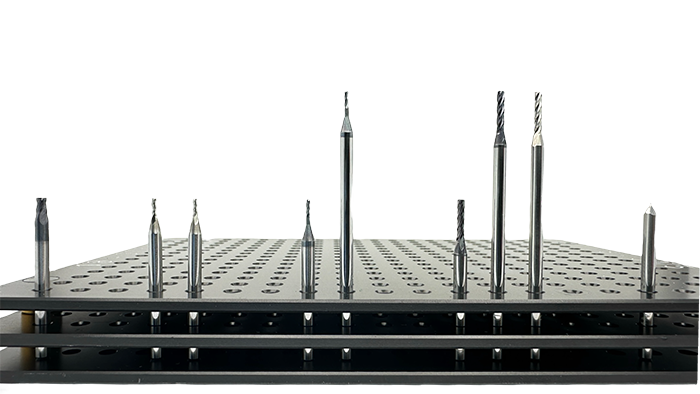

Many consider their first decision in selecting cutting tools is whether they need a custom or standard tool. While this distinction will be decided at some point in every project, we suggest it should not be the first. Sometimes, going into a project with preconceived notions about whether to use a standard or custom tool means you may miss opportunities to make the best decision for the job at hand. Consider lead time, performance goals, and overall project demands – and let those determine which tool is right for the job.

With some basic info about your project, goals, and timelines, MITGI can help recommend the tools that best fit the project. For example, is your work a:

Ready to discuss the options best suited for your project? Let us know. We're happy to help you select the right tool for the job.

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...