2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

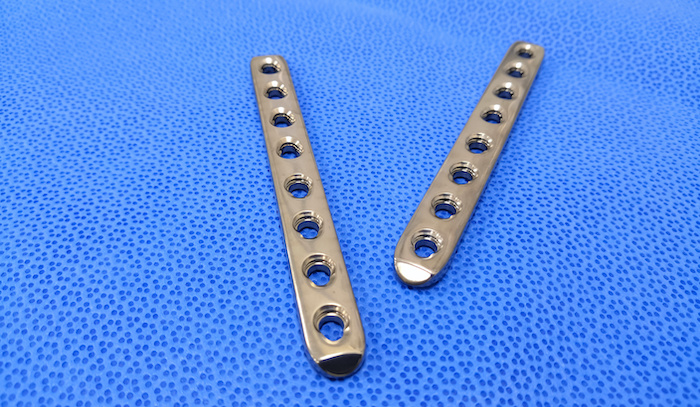

Stainless steel is designed to handle harsh conditions—from seawater, to acids, to bio-corrosion from the human body—and not breakdown. It is used regularly for things like automotive and aerospace parts, medical devices (because of its biocompatibility), and in food handling applications (because it is easily sterilized).

The hardness that gives stainless steel its durability can also make it a challenge to machine. If you’re struggling with getting good cuts or want to extend the life of the tools you use on stainless steel, here are some key things to consider.

Stainless steel absorbs heat. If too much heat stays in the piece you are cutting, it will experience hardening—which will ruin the part. There are several key ways to help control the heat.

Whether you’re cutting 304, 316, 410, 17-4, or any other stainless steel, there are ways to ensure that heat is kept as low as possible. Working with a design team can help to develop the geometry best suited for each specific application.

Several alloys and material grades fall under the category of stainless steel, so guidance on cutting speed ranges and feed rates will vary. In many applications, it may be possible to achieve between 100-350 SFM for stainless steel.

Over the past decade, the use of high efficiency machining methods has made stainless steel easier to mill. Machinists used to move more slowly through stainless and bury a tool deep into it. This works against the natural hardness of the metal. Experts now recommend trochoidal or dynamic motion paths combined with optimized geometry to get the best results with stainless steel.

New grades of stainless steel are constantly being developed as manufacturers search for alloys that deliver the properties they need in their finished products. If the grade of stainless steel you are machining has changed, the tool you are machining it with should probably change, too, especially if you want to optimize how long it lasts.

This could mean reexamining the geometry of the tools, adding a coating, or simply adjusting your feed and speed rates. Here again, expert tool manufacturers will be able to give you insights into matching your tools to your cutting material so you can optimize your operations and your budget.

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...