2 min read

Avoid out-of-tool disruptions and stabilize pricing with blankets

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...

Every week we have conversations with customers about how to customize tool designs to help achieve ideal machining environments and meet performance goals. Sometimes the projects are straightforward, requiring consistency and repeatability. Other times, projects may include complex features, high volume production requirements, or demanding materials. One thing that all projects need - chip evacuation.

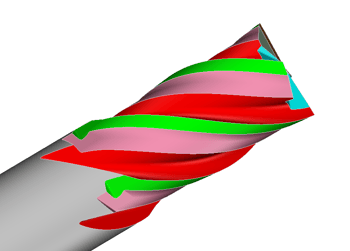

On end mills, the directions of the cut and spiral determine how and where the chips evacuate the cutting area. When the directions are the same as each other (RH cut/RH spiral, or LH cut/LH spiral), the chips will exit out the top and move to either the right or left of the cutting area. When the directions are opposite (RH cut/LH spiral, LH cut/RH spiral), the chips will exit out the bottom and move to either the right or left of the cutting area. Whichever combination is utilized, the goal is the same – get chips out of the way so that the tool can work efficiently.

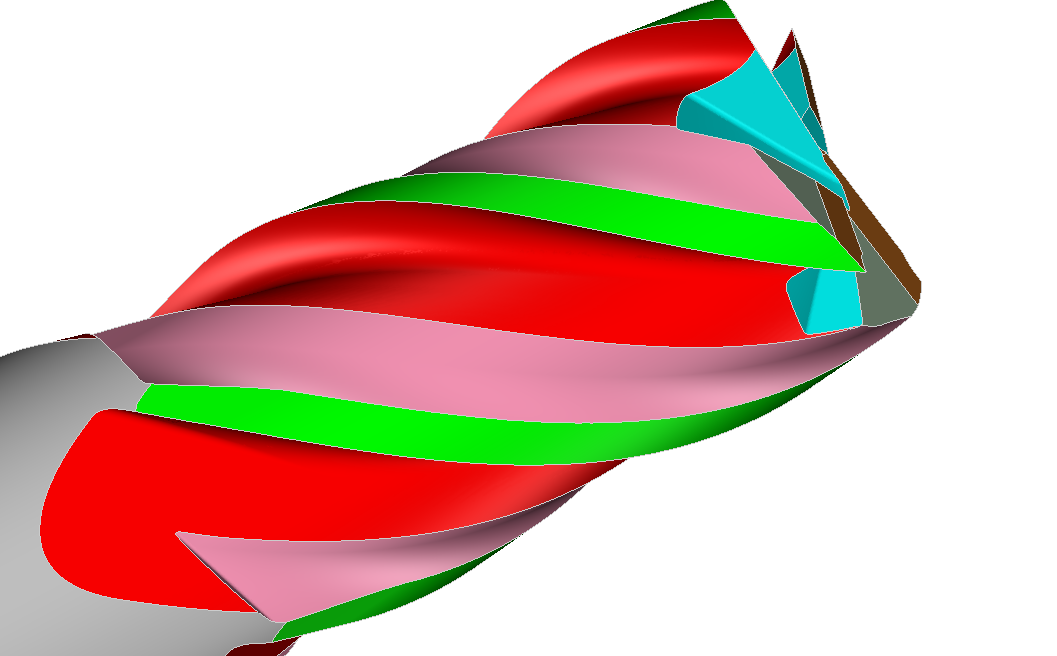

How does it work? With this combination, chips evacuate up and to the right.

How does it work? With this combination, chips evacuate up and to the right.

When to use it? This is the most common cut and helix direction. If nothing specific is requested, this is usually the default option applied. This combination is useful in any application where side or bottom milling are utilized.

Operations: Side milling, bottom milling, plunging, profiling, roughing, finishing, slotting

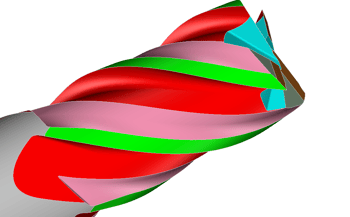

How does it work? With this combination, chips evacuate up and to the left.

How does it work? With this combination, chips evacuate up and to the left.

When to use it? Like it’s RH/RH counterpart, the LH Cut/LH Spiral combination is particularly effective in applications where side or bottom milling are utilized. This combination is often used in mirror image milling operations to keep cutting action the same on both sides of the part and milling in the same direction.

Operations: Side milling, bottom milling, plunging, profiling, roughing, finishing, slotting

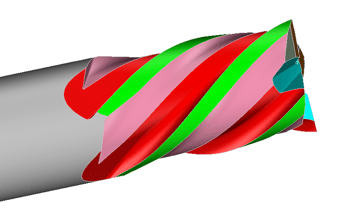

How does it work? With this combination, chips evacuate down and to the right.

How does it work? With this combination, chips evacuate down and to the right.

When to use it? It may be a good option to consider any time the part is being pulled up from the work holding. Downward cutting forces may help to the part to stay secure. In some materials, it may also help to avoid delamination.

When to avoid it? This combination is not recommended in bottom or end cutting operations as the chips are evacuated out the bottom of the tool.

Operations: Profiling, roughing, finishing

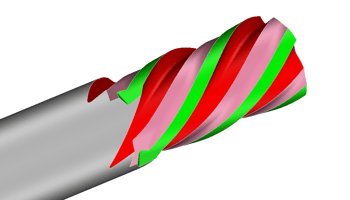

How does it work? With this combination, chips evacuate down and to the left

How does it work? With this combination, chips evacuate down and to the left

When to use it? It may be a good option to consider any time the part is being pulled up from the work holding. Downward cutting forces may help to the part to stay secure. In some materials, it may also help to avoid delamination.

When to avoid it? This combination is not recommended in bottom cutting operations as the chips are evacuated out the bottom of the tool.

Operations: Profiling, roughing, finishing

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...

Mar 27, 2025by MITGI

High-volume, low-mix production environments count on predictability to keep their long-running jobs profitable and on...

Mar 4, 2025by MITGI

When jobs run for many months or years, it may be worth exploring whether there are advantages in moving to a higher...